Revolutionizing Healthcare: Meet the Air-Powered Computer Transforming Medical Device Monitoring!

Air-powered computer for medical device monitoring

Revolutionary Air-Powered Computer Enhances Medical Device Safety

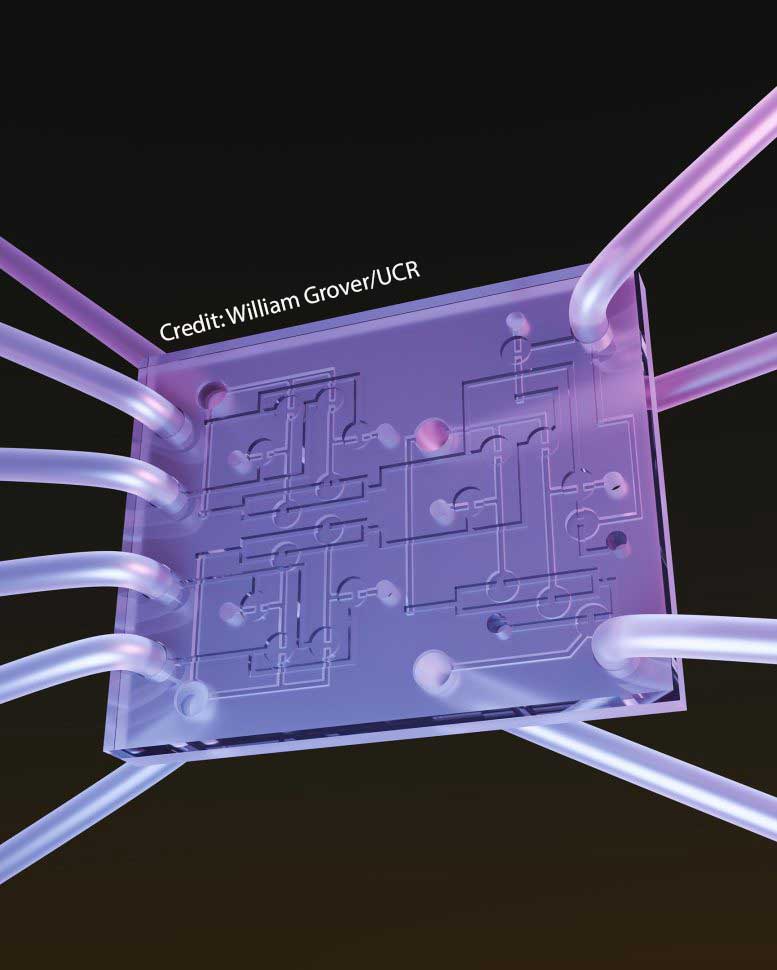

A novel air-powered computer has been engineered to detect malfunctions in medical devices using air pressure, thus eliminating the need for electronic sensors.

This innovation presents a safer, more economical alternative with potential applications in hazardous environments.

Researchers have created this air-powered computer to monitor and alert when specific medical devices fail.

By removing the necessity for electronic sensors, the device offers a streamlined, cost-efficient, and dependable method for preventing blood clots and strokes.

Detailed in a publication in the journal Device, the computer not only operates on air but also utilizes air to sound alarms. It emits a whistle upon detecting a malfunction in the life-preserving compression machine it supervises.

Advancing Medical Safety through Pneumatics

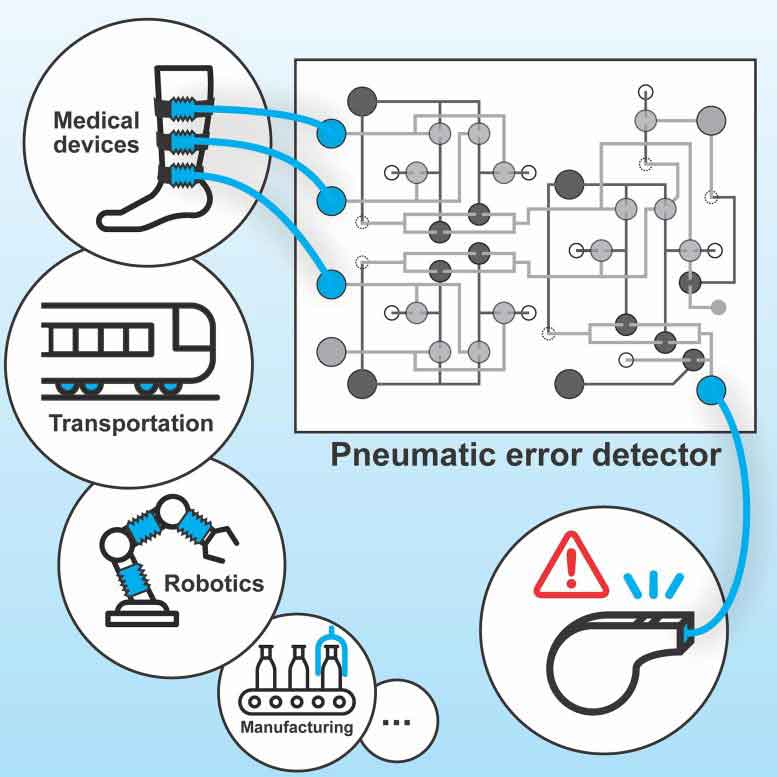

Intermittent pneumatic compression (IPC) devices are designed as leg sleeves that periodically inflate, squeezing the legs to enhance blood circulation.

This action helps prevent the formation of clots, which can lead to blocked blood vessels, strokes, or fatalities. Typically, these devices are driven and monitored by electronic components.

“IPC devices are life-saving, but the electronics within them inflate their costs. We aimed to develop a pneumatic device that could eliminate some of these electronics, making the devices both cheaper and safer,” explained William Grover, associate professor of bioengineering at UC Riverside and lead author of the study.

Technical Overview: The Mechanism of Air-Powered Computers

Pneumatics involves the movement of compressed air through various channels. This principle is applied in systems like freight train emergency brakes, bicycle pumps, tire pressure gauges, respirators, and IPC devices.

Grover and his team realized the potential of using one pneumatic logic system to control another, enhancing safety in the process.

These devices function similarly to electronic circuits, performing parity bit calculations. Grover illustrated, “Imagine sending a message in binary, such as 1-0-1, which consists of three bits.

Decades ago, it was discovered that adding one more bit of information could ensure the recipient received the correct message.”

This additional information is known as a parity bit. It represents a number — 1 if the message contains an odd number of ones and 0 if it contains an even number of ones.

If a message with an even number of bits ends with a 1, it indicates an error. Many electronic computers transmit messages this way.

Air-powered computer for medical device monitoring: Practical Implementations and Future Outlook

The air-powered computer operates by differentiating air pressure through 21 minuscule valves to count ones and zeroes. If counting errors are absent, the whistle remains silent.

However, if the whistle blows, it signals the need for repairs. In a video demonstration, Grover and his students deliberately damage an IPC device with a knife, rendering it inoperative. Within seconds, the whistle sounds.

“This device, about the size of a matchbox, replaces multiple sensors and a computer,” Grover remarked. “Thus, we can lower costs while still detecting device issues. Additionally, it could function in environments with high humidity or temperature, where electronics might fail.”

Monitoring IPC devices is just one potential application of air-powered computing. Grover’s next ambition is to design a device to eliminate a perilous task that claims lives each year — moving grain inside tall silos.

Grain silos, towering structures filled with corn or wheat, are ubiquitous in the Midwest. Often, a person must enter with a shovel to level the grain piles inside.

“A staggering number of fatalities occur when grain shifts, trapping the individual. A robot could perform this task instead. However, these silos are explosive, and even a minor electric spark could cause a catastrophe. Hence, an electronic robot might not be the ideal solution,” Grover explained. “My goal is to create an air-powered robot that could operate in this volatile environment, avoiding sparks, and safeguarding human lives.”

The concept of air-powered computing has existed for over a century. In the past, air-powered pianos played music from perforated rolls of paper. However, with the advent of modern computing, interest in pneumatic circuits waned.

“Once a technology becomes dominant, alternative solutions are often forgotten,” Grover observed. “What excites me about this research is that it demonstrates the relevance of century-old ideas in contemporary scenarios.”

Reference

“Air-powered logic circuits for error detection in pneumatic systems” by Shane Hoang, Mabel Shehada, Zinal Patel, Minh-Huy Tran, Konstantinos Karydis, Philip Brisk, and William H. Grover, published on August 12, 2024, in Device.

Air-powered computer for medical device monitoring