Revolutionizing Electronics: The Game-Changing Technique for Flexible, Transparent Circuits!

ambient printing metal oxide circuits

Researchers have pioneered a method for printing thin metal oxide films at ambient temperatures, resulting in transparent, flexible, and exceptionally conductive circuits. This innovative technique employs liquid metal to deposit solid oxide films that retain their conductive characteristics even at elevated temperatures.

Traditionally, the fabrication of metal oxides for electronic applications necessitated specialized equipment, which was often slow, costly, and operated under high-temperature conditions. Michael Dickey, co-corresponding author of the relevant research paper and the Camille and Henry Dreyfus Professor of Chemical and Biomolecular Engineering at North Carolina State University, emphasizes, “We aimed to devise a technique for the creation and deposition of metal oxide thin films at room temperature, effectively allowing the printing of metal oxide circuits.”

The Significance of Metal Oxides in Electronics

Metal oxides are integral materials found in nearly all electronic devices. While many metal oxides are electrically insulating, some possess both conductivity and transparency, making them crucial for components like touch screens and computer monitors.

Dickey remarks, “In theory, manufacturing metal oxide films should be straightforward. They naturally form on the surfaces of countless metallic objects in our homes, from soda cans to stainless steel cookware. Yet, their utility is often restricted because they cannot be extracted from the metals on which they form.”

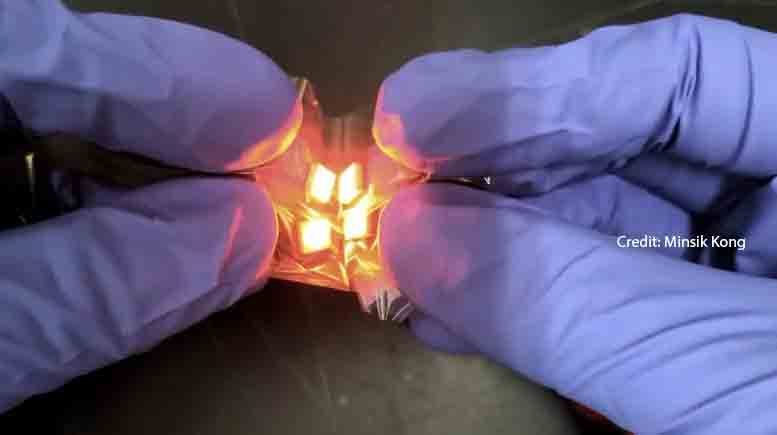

In this research, the team introduced a novel approach to isolate metal oxide from the meniscus of liquid metal. When a tube is filled with liquid, the meniscus—the curved liquid surface extending beyond the tube’s edge—forms due to surface tension, preventing spillage. In the context of liquid metals, this meniscus is enveloped by a thin skin of metal oxide that forms at the air-liquid interface.

“We create a setup where the space between two glass slides is filled with liquid metal, allowing a small meniscus to extend beyond the edges of the slides,” explains Dickey. “The slides function as a printer, while the liquid metal acts as ink. When the meniscus contacts a surface, its oxide-coated sides adhere and detach, akin to a snail’s trail. As this occurs, the exposed liquid continuously generates fresh oxide, facilitating ongoing printing.”

ambient printing metal oxide circuits: Fabricating Thin, Solid Metal Oxide Films

The outcome of this process is the deposition of a two-layer thin film of metal oxide, approximately 4 nanometers thick.

“It’s crucial to note that, despite the use of a liquid medium, the metal oxide film applied to the substrate is solid and remarkably thin,” Dickey notes. “This film bonds to the substrate securely, making it impervious to smudging—an essential feature for circuit printing.”

The researchers demonstrated this technique using various liquid metals and metal alloys, with each altering the composition of the resultant metal oxide film. They successfully created layered thin films by executing multiple passes with the printer. “Surprisingly, the printed films exhibit transparency alongside metallic properties,” Dickey adds. “They possess high conductivity.”

Unyong Jeong, co-corresponding author and professor of materials science and engineering at Pohang University of Science and Technology (POSTECH), comments, “The metallic nature of these films allows for the unusual bonding of gold to the printed oxide. Typically, gold does not adhere well to oxides. When gold is introduced in small quantities to these thin films, it integrates into the film, aiding in the preservation of the oxide’s conductive properties over time.”

Jeong further explains, “The high conductivity may stem from the low oxygen content in the core of the two-layer film, making it more metallic than oxidized. Without gold, increased oxygen diffusion into the film’s center leads to electrical insulation. Incorporating gold helps inhibit oxidation, which is remarkable given the minimal quantity used, allowing the oxide thin film to remain highly transparent.”

Performance at Elevated Temperatures and Flexibility: ambient printing metal oxide circuits

Moreover, the researchers found that these thin films maintained their conductive properties at high temperatures. A film measuring 4 nanometers retains conductivity up to nearly 600 degrees Celsius, while a 12-nanometer film sustains its properties up to at least 800 degrees Celsius.

The utility of this technique was further illustrated by printing metal oxides onto a polymer substrate, yielding highly flexible circuits that retained structural integrity even after being folded 40,000 times.

“The films can also be transferred onto unconventional surfaces, such as leaves, for innovative electronic applications,” Dickey notes. “We are protecting the intellectual property associated with this technique and are eager to collaborate with industry partners to explore its potential uses.”

Reference:

“Ambient printing of native oxides for ultrathin transparent flexible circuit boards” by Minsik Kong, Man Hou Vong, Mingyu Kwak, Ighyun Lim, Younghyun Lee, Seong-hun Lee, Insang You, Omar Awartani, Jimin Kwon, Tae Joo Shin, Unyong Jeong, and Michael D. Dickey, August 15, 2024, Science. DOI: 10.1126/science.adp3299

This research received support from the National Research Foundation of Korea, funded by the Ministry of Science, under grants 2022M3C1A3081359 and RS-2024-00338686.