Revolutionary Battery Tech Could Make Phones Paper-Thin and Cars Drive 70% Further!

lightweight structural batteries Electric Cars and Devices

Revolutionary Lightweight Batteries for Electric Cars and Devices

A groundbreaking structural battery developed by Chalmers University has the potential to significantly reduce the weight of electronic devices and vehicles. By integrating load-bearing and energy storage functions, it could revolutionize both efficiency and design possibilities.

Imagine if vehicles or electronics were built using materials that not only store energy but also support structural integrity. This innovation would drastically cut down on weight and energy consumption. Researchers at Chalmers University of Technology have achieved this with a new structural battery, which could cut the weight of laptops in half, create phones as thin as a credit card, and extend the driving range of electric vehicles by up to 70% per charge.

Breakthroughs in Structural Battery Research

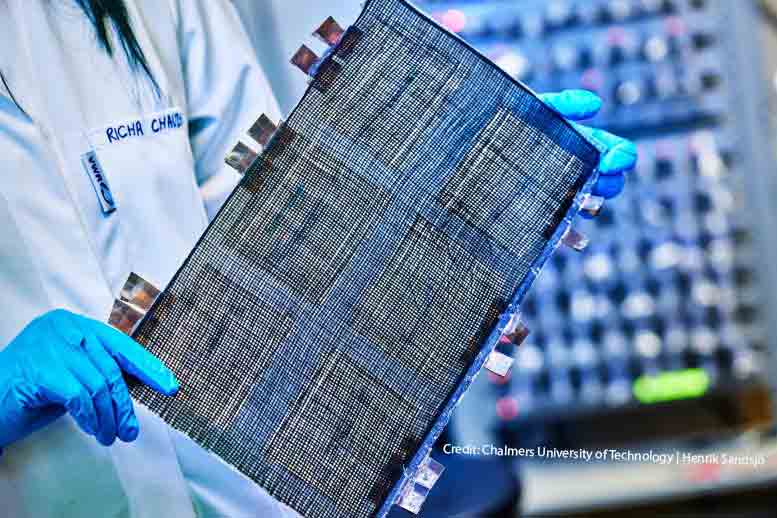

“We have succeeded in designing a carbon fiber composite battery that is as stiff as aluminum while dense enough in energy to be practical,” says Richa Chaudhary, lead researcher and first author of a recently published article in Advanced Materials. “Much like the human skeleton, this battery fulfills multiple roles simultaneously.”

Evolution and Promise of Structural Batteries

Chalmers has been at the forefront of structural battery research for years, working in collaboration with KTH Royal Institute of Technology in Stockholm at various stages. When Professor Leif Asp and his team initially demonstrated in 2018 that strong carbon fibers could also store chemical energy, it drew global attention. The discovery—that carbon fibers can serve as electrodes in lithium-ion batteries—was hailed as one of the top ten breakthroughs of the year by Physics World.

lightweight structural batteries Electric Cars and Devices: Boosting Efficiency in Electric Vehicles

Building on that foundation, the research group has significantly improved both stiffness and energy density. In 2021, they achieved 24 watt-hours per kilogram (Wh/kg), or about 20% of a standard lithium-ion battery’s capacity. The latest iteration boosts this to 30 Wh/kg. Though still trailing current batteries in energy density, the material’s dual role as both a battery and a lightweight structural component drastically reduces a vehicle’s total weight. In an electric car, this could dramatically lower the energy required to operate.

The Future of Lightweight Transport

“Prioritizing lighter, more energy-efficient vehicles is essential for sustainable energy use and future generations,” explains Professor Leif Asp, head of the research team. He notes that their calculations show electric cars equipped with structural batteries could travel 70% farther than current models.

Enhanced Functionality and Strength

For vehicles, structural integrity is critical. The team’s latest battery has markedly increased its stiffness, with an elastic modulus—measured in gigapascals (GPa)—rising from 25 to 70. This allows the material to carry loads as efficiently as aluminum but at a fraction of the weight. “Our new battery outperforms its predecessor in multifunctionality by a factor of two,” Asp adds, hailing it as the most advanced structural battery in existence.

lightweight structural batteries Electric Cars and Devices: Toward Commercialization

From the outset, the goal has been to create a commercially viable structural battery. While research continues, the commercial link is already taking shape through Sinonus AB, a venture based in Borås, Sweden, that was launched by Chalmers Ventures.

There’s still considerable work ahead before these batteries transition from lab-scale production to large-scale manufacturing for consumer devices or vehicles. “Credit card-thin phones and featherlight laptops could be the first applications we see,” Asp predicts, adding that automotive and aerospace industries are showing keen interest in the technology. Significant investment will be required to meet these sectors’ energy needs, but this is precisely where the technology could have the most transformative impact.

The Dual Role of Structural Batteries

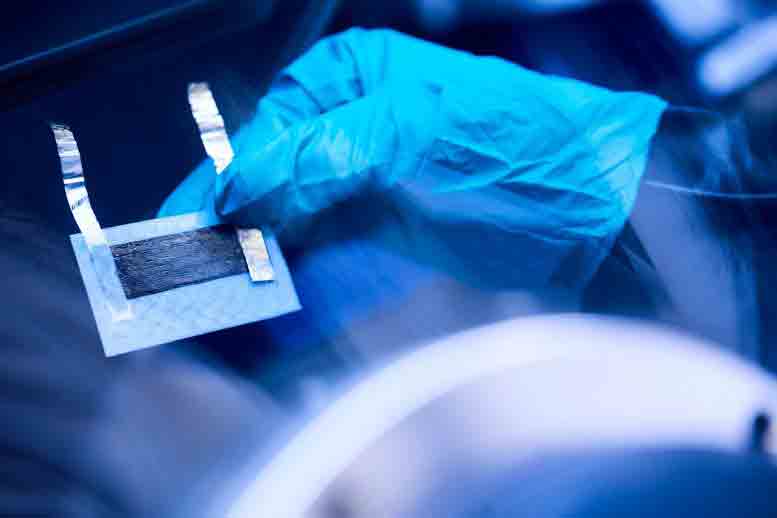

Structural batteries store energy while also bearing loads, which makes them an integral part of the material framework in products like electric cars, drones, and mobile devices. The design, based on carbon fiber composite, incorporates both positive and negative electrodes. Carbon fiber is multifunctional, acting as reinforcement, current collector, and active material within the battery.

By eliminating the need for conventional current collectors—typically made of heavier metals such as copper or aluminum—the overall weight is reduced even further. Furthermore, the design avoids the use of conflict minerals such as cobalt or manganese in the electrode material.

Addressing Safety and Power Efficiency

In this new design, lithium ions are transported through a semi-solid electrolyte, rather than a liquid, which poses challenges in achieving high power outputs and requires further investigation. However, the design also enhances safety by reducing the risk of fire in the battery cell.

Reference

“Unveiling the Multifunctional Carbon Fiber Structural Battery” by Richa Chaudhary, Johanna Xu, Zhenyuan Xia, and Leif E. Asp, published 10 September 2024 in Advanced Materials. DOI: 10.1002/adma.202409725.

This research has been supported by the Wallenberg Initiative Materials Science for Sustainability (WISE) program.