Chilling Consequences: How Low Temperatures Are Sabotaging Your Electronics!

low temperature electronics failure

Researchers Discover Why Next-Gen Electronics Fail at Low Temperatures

New Research Illuminates Degradation Mechanisms in Next-Generation Electronics

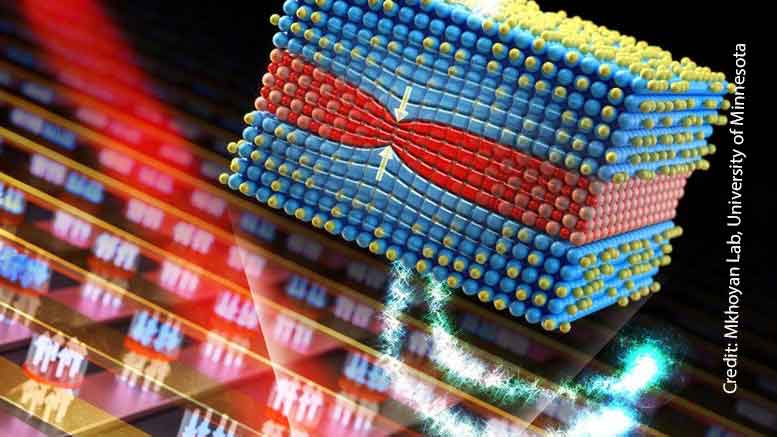

Recent investigations into Spintronic magnetic tunnel junctions have unveiled that these devices exhibit failure at surprisingly low temperatures, thereby offering critical insights for enhancing future electronic architectures.

Degradation of Next-Generation Electronics

A groundbreaking study spearheaded by the University of Minnesota Twin Cities reveals significant insights into the degradation processes of next-generation electronics, notably memory components utilized in computers.

A thorough understanding of the underlying causes of this degradation may lead to enhanced efficiency in data storage solutions.

Published in ACS Nano, a peer-reviewed scientific journal, this research graces the journal’s cover, highlighting its importance.

Advancing Data Storage through Spintronic Technology

As computing technology evolves, the demand for efficient data storage solutions intensifies. Spintronic magnetic tunnel junctions (MTJs) represent a novel class of nanostructured devices that harness electron spin to bolster the performance of hard drives, sensors, and various microelectronic systems, including Magnetic Random Access Memory (MRAM). These MTJs hold promise for future memory devices.

MTJs have become foundational elements for non-volatile memory in applications ranging from smartwatches to in-memory computing, with aspirations for enhancing energy efficiency in artificial intelligence systems.

low temperature electronics failure: Real-Time Observation of Device Degradation

Employing a sophisticated electron microscope, researchers scrutinized the nanopillars—minuscule, transparent layers within the device. By passing a current through the device, they meticulously observed its operational dynamics.

Gradually increasing the current allowed for real-time observation of the degradation process culminating in device failure.

“Conducting real-time transmission electron microscopy (TEM) experiments presents considerable challenges, even for seasoned researchers,” noted Dr. Hwanhui Yun, the paper’s first author and postdoctoral research associate at the University of Minnesota’s Department of Chemical Engineering and Material Sciences.

“However, through numerous iterations and optimizations, we consistently produced viable samples.”

low temperature electronics failure: New Insights into Electronic Failure Mechanisms

This innovative approach led to the revelation that prolonged exposure to a continuous current causes the device layers to constrict, ultimately resulting in malfunction.

While earlier studies had speculated on this phenomenon, this research marks the first direct observation of such effects.

The formation of a “pinhole”—a consequence of this constriction—signals the onset of degradation. As current levels escalate, the device succumbs to thermal meltdown, completely failing.

“What stands out about this discovery is the observation of burnout occurring at significantly lower temperatures than previously hypothesized,” remarked Andre Mkhoyan, the senior author of the study and a professor at the University of Minnesota’s Department of Chemical Engineering and Material Sciences.

“This temperature is nearly half of what had been anticipated in earlier research.”

low temperature electronics failure: Future Implications for Electronic Design

A closer examination of the device at the atomic scale revealed that materials at this minuscule size possess markedly distinct properties, including altered melting temperatures. Consequently, the failure timeline of the device diverges sharply from prior understanding.

“There has been a pressing need to comprehend the interfaces between layers in real time under authentic operational conditions, such as applying current and voltage; yet, this level of understanding had not been achieved until now,” stated Jian-Ping Wang, a senior author and Distinguished McKnight Professor at the University of Minnesota’s Department of Electrical and Computer Engineering.

“We are thrilled to announce that our findings will have a direct impact on the design of next-generation microelectronic devices within the semiconductor industry,” Wang added.

The researchers aspire that these insights will inform future enhancements in computer memory unit design, aiming to bolster longevity and efficiency.

Reference

“Uncovering Atomic Migrations Behind Magnetic Tunnel Junction Breakdown” by Hwanhui Yun et al., 20 August 2024, ACS Nano. DOI: 10.1021/acsnano.4c08023

In addition to Yun, Mkhoyan, and Wang, the team included postdoctoral researcher Deyuan Lyu, research associate Yang Lv, former postdoctoral researcher Brandon Zink, and colleagues from the University of Arizona’s Department of Physics.

This research was supported by SMART, one of seven centers within nCORE, a Semiconductor Research Corporation program sponsored by the National Institute of Standards and Technology (NIST); funding from the University of Minnesota Grant-in-Aid; the National Science Foundation (NSF); and the Defense Advanced Research Projects Agency (DARPA). The collaboration also involved the University of Minnesota Characterization Facility and the Minnesota Nano Center.